Moving Forward in 2021 during a Global Pandemic with VUCA Lessons.

Moving Forward in 2021 during a Global Pandemic with VUCA Lessons.

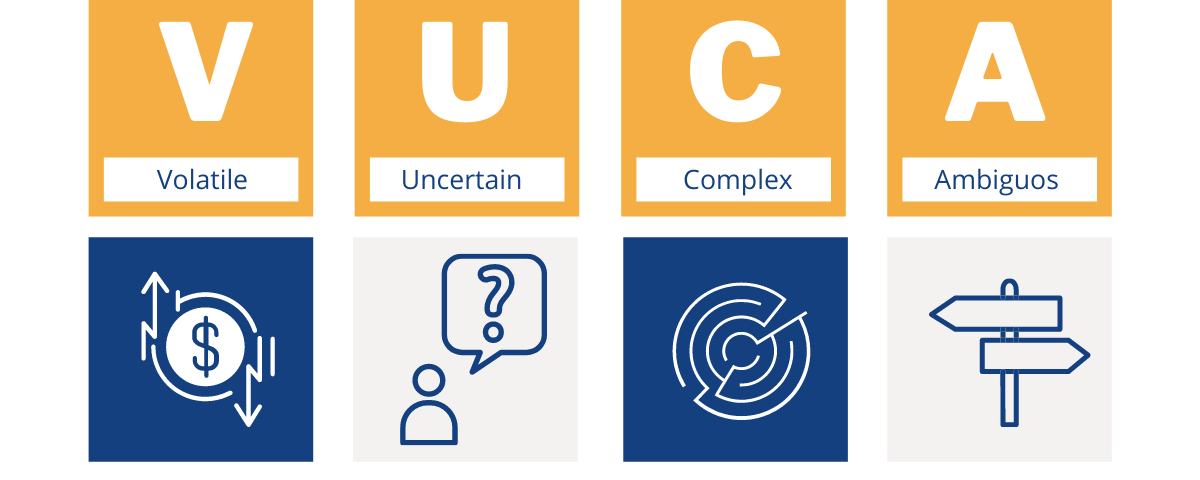

Supply chain specialists identified VUCA as volatile, unpredictable, complex, and ambiguous just a few years ago. VUCA has been synonymous with the global pandemic since the international supply chain disruptions in 2020 (some of which are still being seen and felt today).

VUCA has taken on new significance as we approach 2021, no matter how you slice it. Supply chain executives must evaluate how VUCA situations might affect local, regional, national, and global operations, as well as what can be done to improve resilience and responsiveness.

Let’s take a closer look at this.

What is VUCA?

For clarity, here are some definitions:

- Volatile: large-scale shifts or swings that occur without warning

- Uncertain: a future that is unpredictable with certainty

- Complex: multi-layered difficulties impacted by a large number of moving elements

- Ambiguous: a lack of understanding of events and their consequences

While firms in the United States witnessed the epidemic move from China to many other areas of the world before arriving on American soil, we were caught off guard as to how it would effect our operations and the supply chain in general.

Developing Resilience Using VUCA Characteristics

In the year 2020, the main topic was just to survive. To keep the lights on and the doors open, companies had to abruptly shift gears, try new technologies and processes, seek out new vendors and routes to market, and employ a myriad of other experimental approaches.

We’re still not quite “back to normal,” but the dust has settled. Companies may now look back on what worked and what didn’t in the previous year and utilize that information to become more resilient in the future. Learning, testing, and evolution that would have taken years in the past have all been completed in a few of months.

That is why the theme for 2021 isn’t only to survive, but to flourish.

Now is the moment to assess VUCA’s influence on your supply chain operations during the previous year. Here are some questions that might help your leadership team have meaningful discussions:

- What were the most significant negative effects of VUCA on our business last year (e.g., client loss, longer lead times, unanticipated technology investments, etc.)?

- What were the most significant positive effects of VUCA on our business last year (for example, new client acquisition, increased market share, leaner processes, and so on)?

- Which areas of weakness do we need to address that we weren’t aware of before the pandemic?

- How can we better react to volatility? Uncertainty? Complexity? Ambiguity?

- What can we do now to prepare for the year 2022 and beyond?

Operating in a continual VUCA state of mind, which we’ll discuss in our upcoming blog article, is one notion worth considering that can answer all of the above problems.